Traditional steam boilermakers.

Our family business offers complete steam boiler repair service. We focus on traditional construction methods to the original design. The range of work depends on the condition of the boiler but we try to salvage as much of the original as possible to retain the historical value of the boiler and therefore it’s engine.

We have repaired steam railway locomotives, traction engines, road rollers and portable steam engines. From fireboxes and tubeplates to throatplates and backheads. Have a scroll through some of our previous work below.

Manufacturers, although generally following similar overall design of boiler, had their particular design features. Firebox and outer wrapper construction is interesting when you compare the detail. This shows a Burrell firebox on the right and a couragated crown Fowler design on the left.

This is a ‘Garrett style’ box fitted to a very late Aveling. I think that there are only two Avelings in preservation with this style of fire box.

A firebox design where crown stays are fitted between the crown of the firebox and the outer wrapper. You can see the pre-drilled holes for the stays and the fusible plug position.

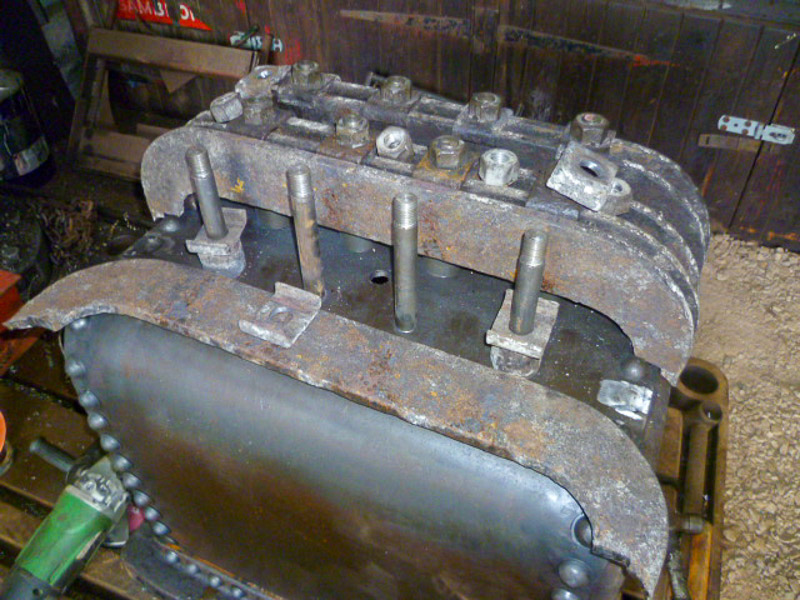

Fireboxes have different methods to support the firebox crown. Here we are fitting the original girder bars with new studs. We can also cut new girder bars on site.

We have a special fondness for portable engines, in particular Brown & May portables. Recently we have been working on B & M 4561 of 1890. Here are a couple of photos of her firebox showing the original girder bars refitted for correct loading.

We have recently done a number of Fowler design fireboxes. In this cases the main firebox crown is supported by vertical crown stays but extra support is required at the front of the box, and this is provided a a short girder bar, as shown in the photo below.

This is the firebox for a colonial Ransomes, Sims and Jefferies direct ploughing engine. It has 50 crown stays !

This is an American design with wet bottomed firebox. This photo shows prefitting the crank brackets and chassis rails to the outer wrapper. All the fixings require positioning prior to fitting the backhead/box assembly. These will then be removed to allow the box to be fitting and stayed.

This is the wet-bottomed firebox and backhead assembly for the Aultman Taylor traction engine. It is a very interesting machine to rebuild due to the original construction design. Take a look……

Outer wrapper repairs can be just barrel sections as shown below. This is a Marshall Britannia boiler design, with circular firetube. The small pad at the top in the photo is for the factory fitted safety valve. They seem to deteriorate around here between the crank brackets.

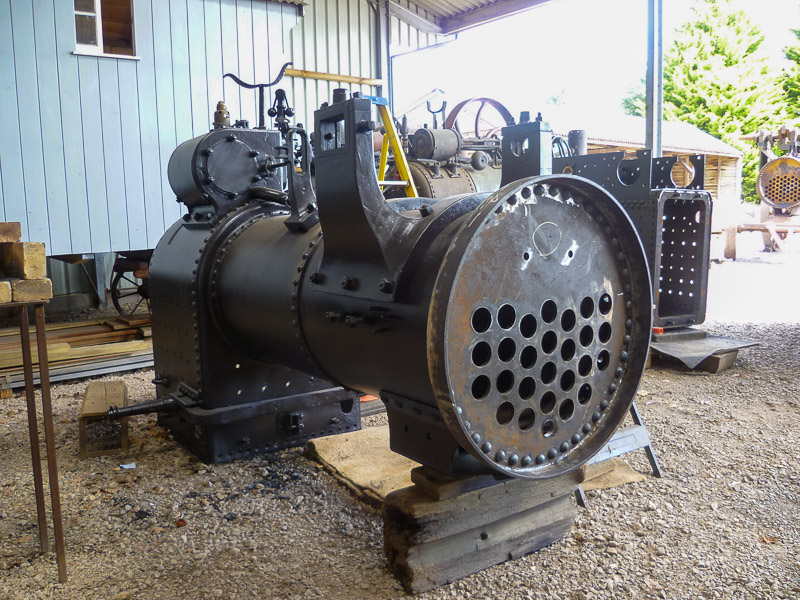

The boiler of the Aveling & Porter M Class convertible engine nearing completion.

Robey portable engine of 1882. New backhead, new firebox and tubeplate.

The firebox in place, now drilled for rivetting and stays.

The new backhead was made, here at home. The regulator box had to be fitted prior to the firebox since on this early type it is internal.

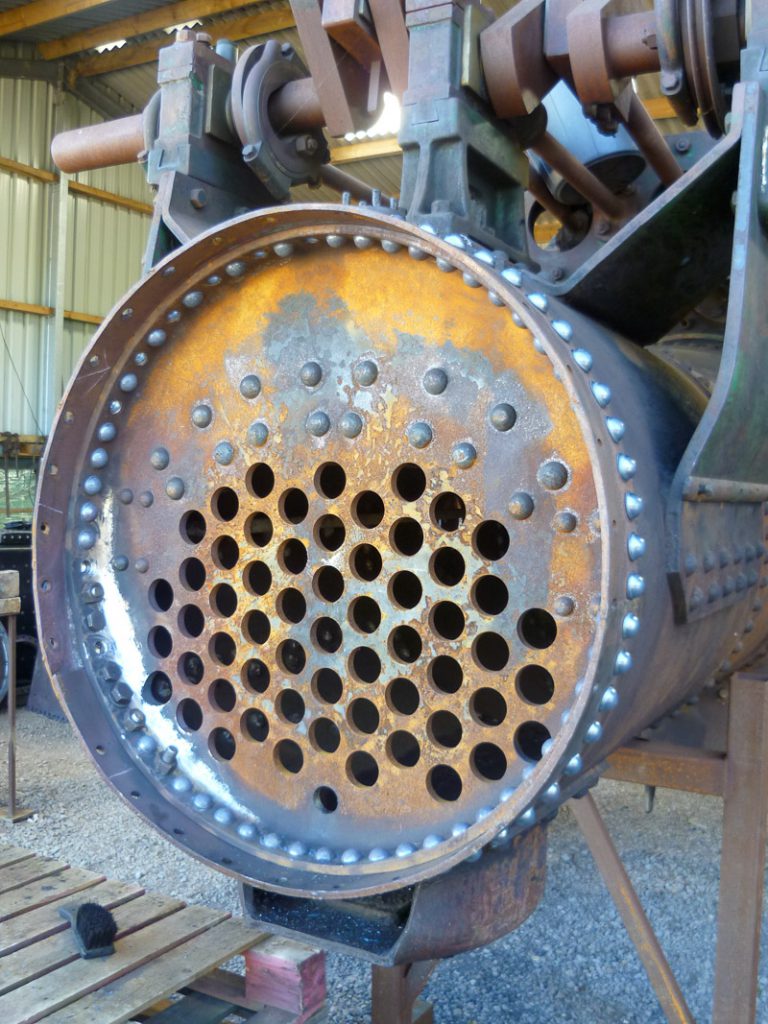

New tubeplate and angle ring – there are photos below of this being made.

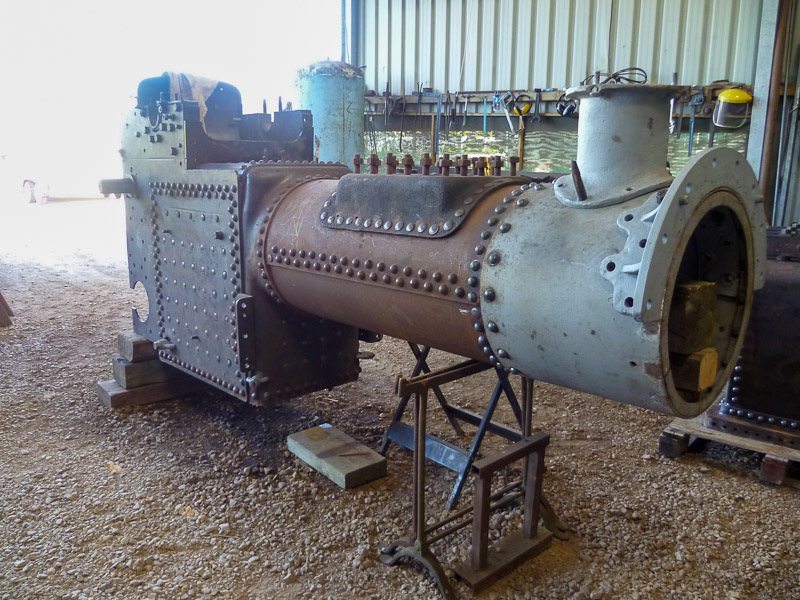

This is the boiler once stripped of the front end and the backhead removed.

Here is a photo of the big Ransomes direct ploughing engine. The boiler work is now complete. We were blanking off the fittings and fitting the mudlids today so here she is with the ‘team’.

New hot pressed tubeplate for a 16hp Marshall portable engine. Ready now to have it’s new smokebox fitted.

Independent Non Destructive Testing (NDT) testing is carried out on site.